Are you familiar with the filter cartridge winding machine? This innovative equipment plays a crucial role in the production of filter cartridges, ensuring efficient and high-quality manufacturing processes. In this article, we will explore how the filter cartridge winding machine works and its effective utilization in various industries.

The Functionality of Filter Cartridge Winding Machine

The filter cartridge winding machine is specifically designed to wind yarn or thread around a core to create a cylindrical structure known as a filter cartridge. It operates through an automated process that ensures precision and consistency in each winding cycle. By utilizing advanced technology, this machine can produce large quantities of high-performance filter cartridges within minimal timeframes.

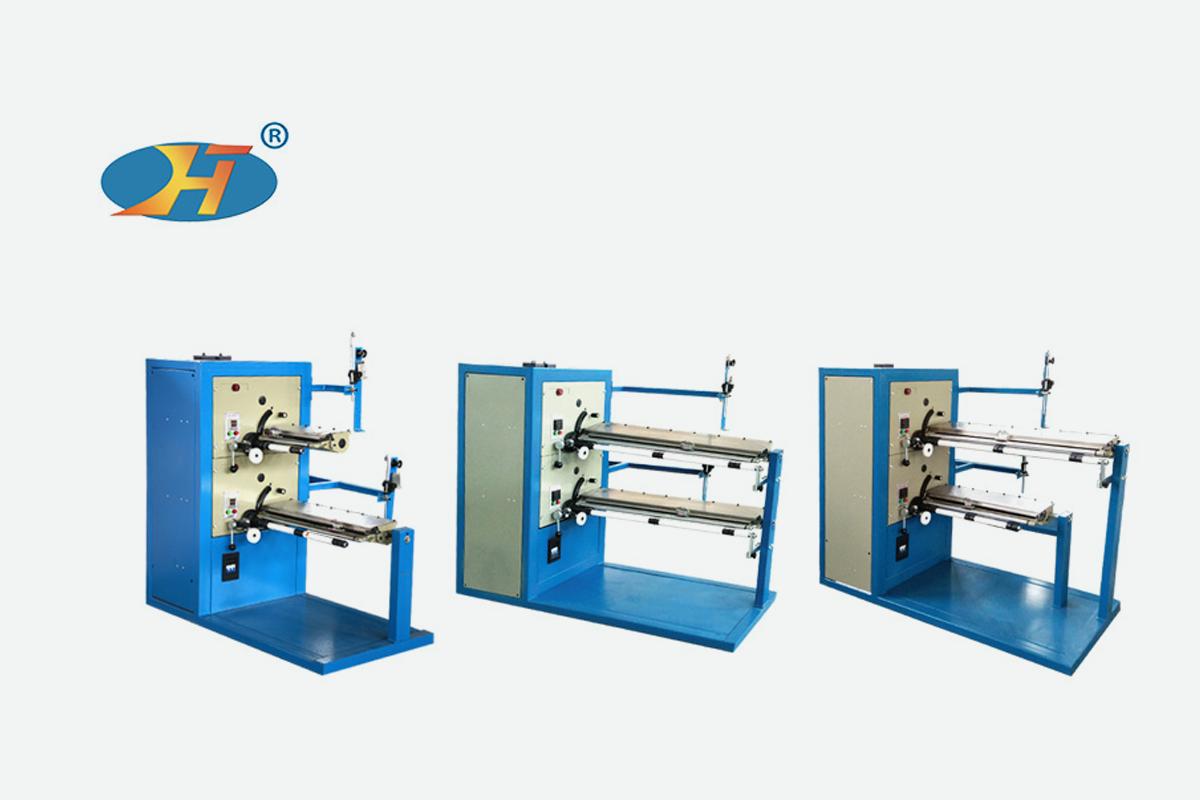

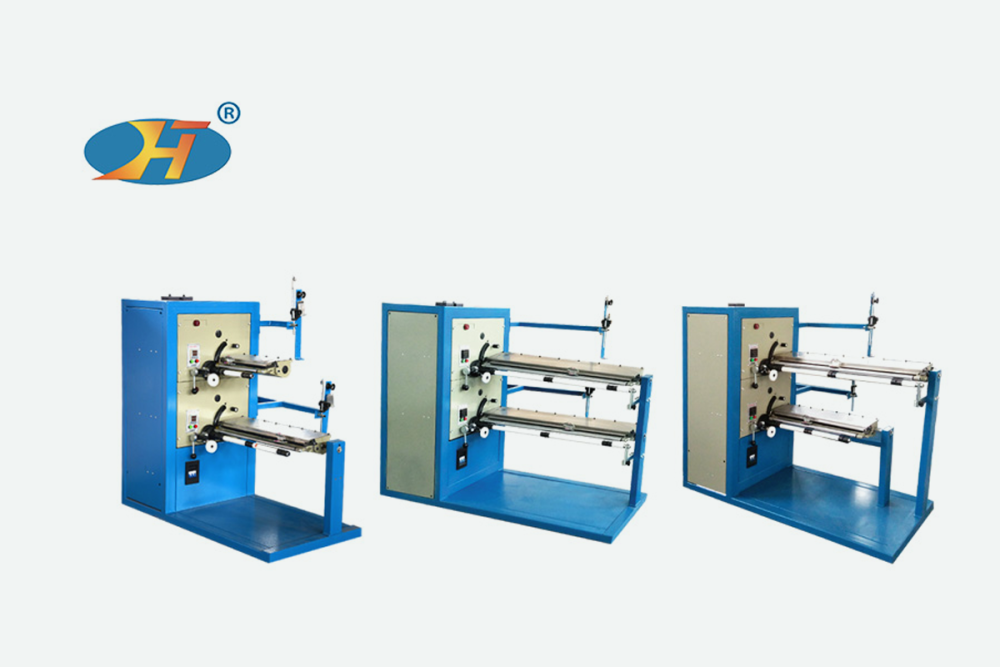

This sophisticated equipment consists of multiple components such as spindles, tension control systems, guiding devices, and cutting mechanisms. The spindles hold the core material while the yarn is wound around it under controlled tension. The guiding devices ensure proper alignment during the winding process to maintain uniformity throughout the entire length of the cartridge.

Additionally, modern filter cartridge winding machines are equipped with cutting mechanisms that precisely trim excess yarn at both ends of each completed cartridge. This feature eliminates manual trimming requirements and enhances overall efficiency.

Hongteng: A Leading Manufacturer of Filter Cartridge Winding Machines

Hongteng is renowned for its expertise in manufacturing top-notch filter cartridge winding machines. With years of experience and continuous innovation, Hongteng has become a trusted name in providing reliable solutions for various industries’ filtration needs.

Their range of filter cartridge winding machines offers exceptional performance capabilities combined with user-friendly interfaces. These machines are engineered to handle different types and sizes of cores along with versatile options for yarn materials like polypropylene (PP), cotton, or polyester. Hongteng’s commitment to quality ensures that their machines deliver precise winding results consistently.

PP Yarn Filter Cartridge Making Machine: A Specialized Solution

The pp yarn filter cartridge making machine is a specific type of filter cartridge winding machine designed for manufacturing polypropylene yarn-based cartridges. This specialized equipment caters to industries where PP yarn filters are widely used due to their excellent chemical resistance and high dirt-holding capacity.

The PP yarn filter cartridge making machine incorporates additional features such as temperature control systems and advanced tension adjustments specifically tailored for processing polypropylene materials. These enhancements ensure optimal performance during the winding process, resulting in superior-quality PP yarn filter cartridges with enhanced filtration efficiency.

Conclusion

In conclusion, the filter cartridge winding machine revolutionizes the production of filter cartridges by providing an efficient and reliable solution. With its automated functionality and precision-driven mechanisms, this equipment streamlines the manufacturing process while maintaining consistent quality standards. Manufacturers like Hongteng offer cutting-edge solutions like the PP yarn filter cartridge making machine, catering to specific industry requirements effectively. By utilizing these advancements in technology, businesses can enhance their filtration capabilities and meet diverse filtration needs efficiently.